Maximack India Pvt. Ltd. is a reputed company that specializes in manufacturing and supplying various industrial machinery, including Rubber Moulding Press machines. Rubber Moulding Press machines are widely used in the rubber and polymer industries for molding and shaping rubber materials into desired forms. While I don’t have specific information about Maximack India Pvt. Ltd.’s Rubber Moulding Press machines, here is some general content you may find useful:

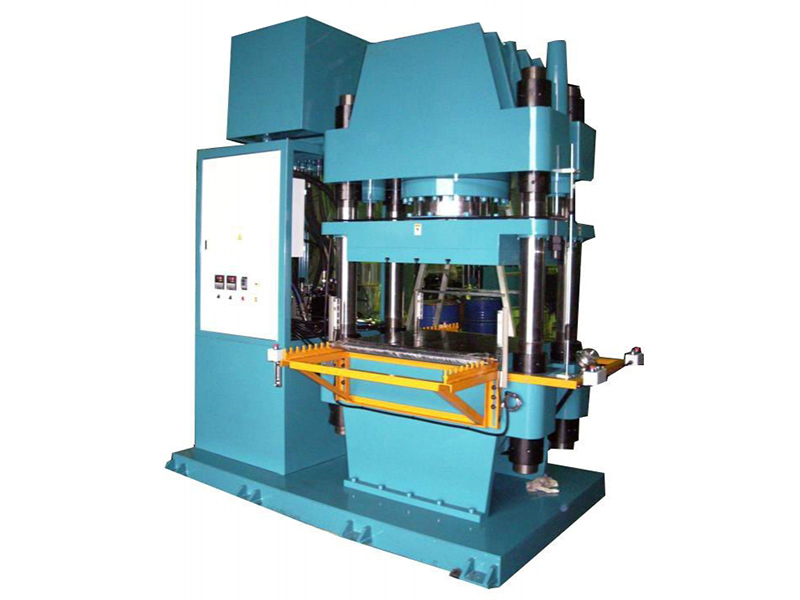

Design and Construction: Rubber Moulding Press machines are designed with a robust frame and a hydraulic system for generating pressure. They typically feature a heated platen or mold assembly where the rubber material is placed for molding. The machines may have multiple platens for accommodating different mold sizes and configurations.

Molding Process: Rubber Moulding Press machines employ a combination of heat and pressure to mold rubber materials. The process involves placing the rubber material into the mold cavity, closing the press, and applying heat and pressure to shape the material. This can be done using various molding techniques such as compression molding, transfer molding, or injection molding.

Tonnage Capacity: Rubber Moulding Press machines come in different tonnage capacities to handle a wide range of molding requirements. The tonnage capacity determines the maximum amount of force that the machine can apply during the molding process.

Control System: These machines often incorporate advanced control systems for precise operation. The control system may include features such as temperature control, pressure control, and programmable settings to ensure accurate and repeatable molding results.

Heating System: Rubber Moulding Press machines are equipped with heating systems to heat the platens or mold assemblies. The heating system can use electric heaters, oil heaters, or steam heating depending on the specific machine and application requirements.

Safety Features: Safety is of paramount importance in Rubber Moulding Press machines. They are equipped with safety devices such as emergency stop buttons, safety interlocks, and guards to protect operators during the molding process and prevent accidents.

Customization Options: Manufacturers like Maximack India Pvt. Ltd. may offer customization options for Rubber Moulding Press machines to suit specific customer needs. This can include customization of tonnage capacity, platen size, heating system, control system features, and additional functionalities.

After-Sales Support: Reputable manufacturers typically provide after-sales support, including installation, training, and maintenance services. This ensures that customers receive proper assistance in setting up and maintaining their Rubber Moulding Press machines, as well as optimizing their performance.

For detailed information about Maximack India Pvt. Ltd.’s Rubber Moulding Press machines, I recommend contacting the company directly or visiting their official website. They will be able to provide specific product details, technical specifications, and any customization options available for their Rubber Moulding Press machines.